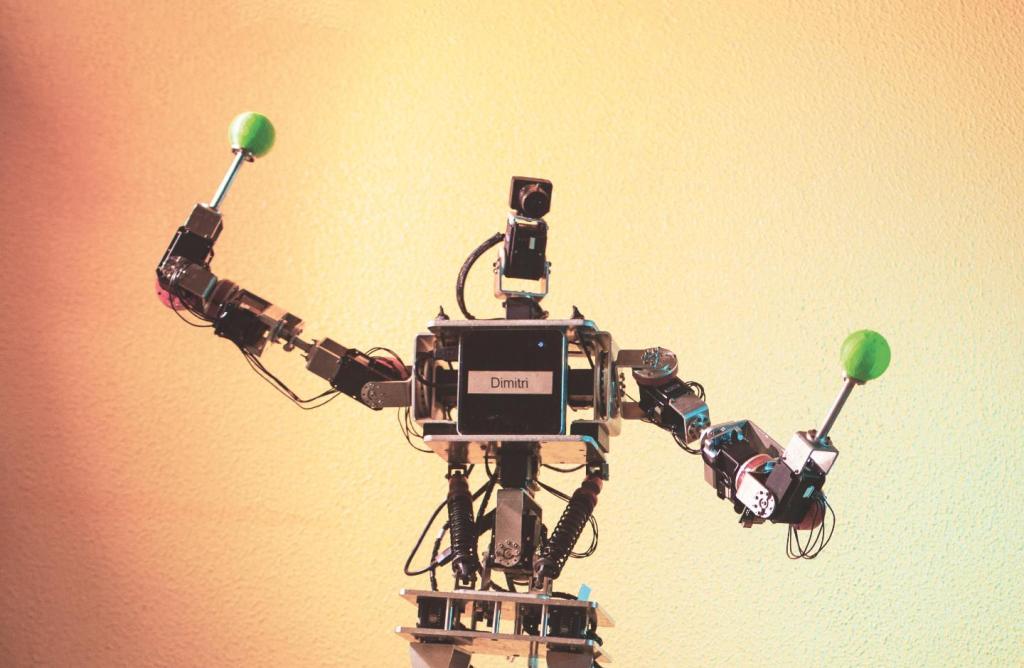

TauraBots, the UFSM humanoid robot soccer team, has a new teammate: the robot Dimitri. The new android is the first to be funded through international cooperation between UFSM and a laboratory at the Korea Advanced Institute of Science and Technology (KAIST) in South Korea. Dimitri is aiding researchers in the field of cognitive robotics by enabling them to test computational models of cognitive development in a physical robot.

The partnership was initiated after a meeting between UFSM professor and project supervisor, Rodrigo Guerra, and the director of the South Korean laboratory, Jun Tani. Built in late December of 2015 and exported to Korea, the robot is composed of a torso, head and compliant robotic arms that give it sensitivity for dynamic manipulation, enabling it to understand when it is squeezing an object, for example.

A second Dimitri was built and is kept at UFSM to help exchange code in cooperation with the Korean lab. The android in Brazil also has two legs and is about 1.24 meters tall, one of the largest humanoid robots ever designed in Brazil.

The idea for its name came from a project member, who said that the robot was “tough like a Russian actor”, so the invention should be given a Russian name. According to the developers, you could throw a concrete block at Dimitri without damaging it.

Connection

The aim of the project is that when the Santa Maria team improves the functionality of the machine, this information can be used in South Korea – and vice versa – since both robots are based on the same system, which facilitates the replication of results.

The most distinguishing feature of the Dimitris is that they have special series elastic actuators (SEAs) in their arms and legs. SEAs are a kind of actuator where springs are placed in series between the motor and the joints and they can be placed in any joint of the body. Traditional robots without this technology have stiffer and more fragile joints that don’t handle unpredicted external forces well, such as when someone pushes the robot’s arm, for example.

With this innovation developed at UFSM, the robots maintain compliance with the environment when they are under strain, which increases the safety of the interaction, both for the robot and, more importantly, for people working with it.

Investment

Developing this kind of technology requires a large financial investment: each robot costs at least US$16,500, according to Professor Guerra. The electric motors alone, used in the Brazilian Dimitri – which were reutilized from another project – cost around US$1,000 each, totaling approximately US$13,200.

Professor Guerra, who resorted to using his own financial resources in the project, points out that Dimitri’s importance for the future justifies its high cost of development. “Dimitri is a robot that, for now, has no pretension to handle household problems, wash dishes or help people with special needs, for example, but it explores this type of technology, which is a step in that direction,” he says.

| Dimitri’s developers chose to make the files used to build the robot available to anyone who wants to contribute or even copy the invention. The software and more information about the project can be obtained by contacting the team at facebook.com/taurabots Image caption: Development of the elastic series actuator required almost two years of research. It is compact, low-cost and is made of a low-density polyurethane elastomer material. |

Reporter: Gabriele Wagner de Souza;

Photographer: Rafael Happke;

Graphic Design: Kennior Dias and Taynane Senna.

Published 2017